Back chipping in welding pdf

7/05/2003 · The back chipping was the cutting out of base metal to get to fully fused base and weld metal. For thin welding in aluminum, I’d actually recommend that you …

This new technology can realize no back chipping for thick plate welding. Furthermore, it has the potential advantages for the implementation of automatic welding for thick plate. Furthermore, it has the potential advantages for the implementation of automatic welding for thick plate.

Australia’s leading online specialty welding shop. Selling a full range of welding machines, cutting machines, safety equipments, accessories and consumables at heavily discounted prices.

are you talking about fixing a defect or doing the root by back welding the i.d. butt weld, i worked for a company in ventura, calif, vetco was its name before combustion engineering bought them out.

ORIGINAL ARTICLE The realization of no back chipping for thick plate welding Chengdong Yang & Jiyong Zhong & Yuxi Chen & Huabin Chen & Tao Lin & Shanben Chen

Lane Community College 2014 Advanced Technology Division Fabrication/Welding Technology FABRICATION/WELDING REQUIRED TOOLS & SUPPLIES LIST FABRICATION WELDING 1 FABRICATION/WELDING 3

Welding Slag Clear Machine with Kinematic Linkage Indexer 1Akshay Mahale, 2Madhavrao Londhe, A. J .Patil 1,2,3 atmospheric gas back, preventing oxidation. ) Slag is great for protecting the weld while it cools, but once it has done its job, it has to be removed before the next pass. So, there are many ways to remove welding slag, but the most common method in years past was with a Chipping

Black Steel Welding / Chipping Hammer Product Code: HAMW-300B 300gram Thanks for taking the time to look at our auction, here are a couple of points to c…

Before deciding on an edge preparation for aluminum welding, there are several influential factors, which have to be considered such as welding position, use or non-use of backing aids, heat sink characteristics, and whether or not back chipping will be required.

13/08/2018 · What is meant by back chipping in welding – Find out more explanation for : ‘What is meant by back chipping in welding’ only from this channel. Information Source: google.

Chipping Hammer eBay

Black Steel Welding / Chipping Hammer Trade Me

flying debris when you use the chipping hammer and wire brush on the weld. 5 Page Vintage helmets with a fixed shade lens (on right) can be a cheaper alternative to the more modern helmet complete with auto-darkening lens (on left). Welding, Cutting and Brazing Student Safety Guidelines Oxygen/Acetylene Welding (Gas Welding) For gas welding, welding goggles, welding glasses, a welding …

Welding Accessories. Electrode Holders Cable Connectors Machine Couplings Earth/Ground Clamps Rotary & Magnetic Ground Clamps Chipping Hammers Cable Lugs & Splicers C & F Clamps Tank Wrenches Brass Hose Fittings Hose Pipes Helmets & Handshields Welding & Battery Booster Kits Welding Goggles Welding Curtains & Booths Pipe Stands Welding Tables Cylinder Carts Cylinder …

Weld residual stresses in a thick plate considering back chipping: Neutron diffraction, contour method and finite element simulation study

Put on all of your safety gear. This is the mask, safety goggles and gloves. Wear goggles under the mask to protect from hot slag and debris. If the mask is the handheld face shield type, set it aside until you need to weld.

a range of welding helmets and filters with features that are just right for you. Follow the easy-to-use selection guide below to find the helmet and filter with features …

A lightweight, reliable design with long handle & double ended chipping head. Features a chisel end and a pointed tip to efficiently remove slag created when welding. Features a chisel end and a pointed tip to efficiently remove slag created when welding.

The residual stress of conventional welding (CW) or a single arc welding (SAW) is calculated too. Moreover, the welding residual stress field of thick metal plates welded by DSDAW was carried out and compared with that of the CW method with back chipping. The result shows that the DSDAW technology had some excellent characteristics of smaller angular deformation, lower residual peak …

Numerical Simulation of Double-Sided Double Arc Welding without Back Chipping Based on MSC.MARC p.1512 Numerical Simulation of Influences of Preheating and Postweld Heat Treatment in Welding

General Field Welding Procedures Brush and/or Chipping Hammer . Spatter: Small Pieces of Metal Scattered Over Weld Surface and Base Metal . Spatter. Seal Weld Occasionally Used to Seal Out Moisture Not a Structural Weld Should be Visually Inspected . Safty Do not watch the welding with out a welding helmet Do not touch the red hot stuff . Title: INSPECTION OF Author: Government …

4/03/2011 · The welding symbol you describe could go either way as there is no technical difference in the symbols for back or backing welds. The symbol is a …

28/03/2010 · Back grinding or chipping is done to remove slag on multiple pass welds. You do not want slag or any other impurities to be embeded in the weld. Reply: Anonymous Poster #5 In reply to #3. Re: Question on welding 03/27/2010 4:03 AM. Back grinding or chipping is done to remove slag on multiple pass welds. You do not want slag or any other impurities to be embeded in the weld. Is technically

Welding School of Industrial, Computing & Engineering Technologies Hager Lifelong Education Center Rm B1134- 570-327-4520 Tools: Striker/triple flint

SCALING PNEUMATIC CHIPPING HAMMER Now chipping after welding is easy! The AIR CHIPPER are compact, lightweight and economical tools to have on hand for all kinds of

When welding like this, positive to the piece will create more heat and deeper penetration with less weld width, where negative to the piece will mean less penetration and wider weld width. As a guide negative to the hand piece for heavier materials and positive for light materials.

solidified glassy product, slag should be removed by chipping or with a wire brush. Gas metal arc welding (GMAW): This process is also referred to as metal inert-gas (MIG) welding uses an …

back chipping root smaw e 7018/3.2 ep 118-120 27-29 100 – 125 istpass smaw e 7018/4.00 ep 161-164 29-31 100 – 125 iindpass smaw e 7018/4.00 ep 162-164 29-30 100 – 125 iii

CHIPPING HAMMERS LH2 Chisel and pick Spring Handle LWHH Chisel and pick Hickony Handle LWHCM Big mike cross chisel and pick Hickony Handle LPHHC Cross Chisel and pick Plastic Handle LAW-1 Hammer and brush Wood Handle. Title: WELDING ACCESSORIES FLYERS.indd Author: michelle Created Date: 10/1/2015 1:51:25 PM

difficult to perfo~ back-chipping at a rate of 0.4 m/min with conventional cutting tools because of the high hardness of the weld metal, inadequate rigidity of the machine~utting tool-job system, and the intermittent nature of cutting,

Product Features: For use after completing a welding job. Chip away extra metal build up with the pointed hammer. You can then proceed to scrape and file down the remaining slag to a more smoother clean surface.GENERAL USAGE: This is the hammer for welding.

FS- Page 1 JOB SAFETY ANALYSIS Safety Information for the University of California, Berkeley FACILITIES SERVICES USING AN OXY-ACETYLENE WELDER * A welding area of a minimum of 35 feet in diameter must be established.

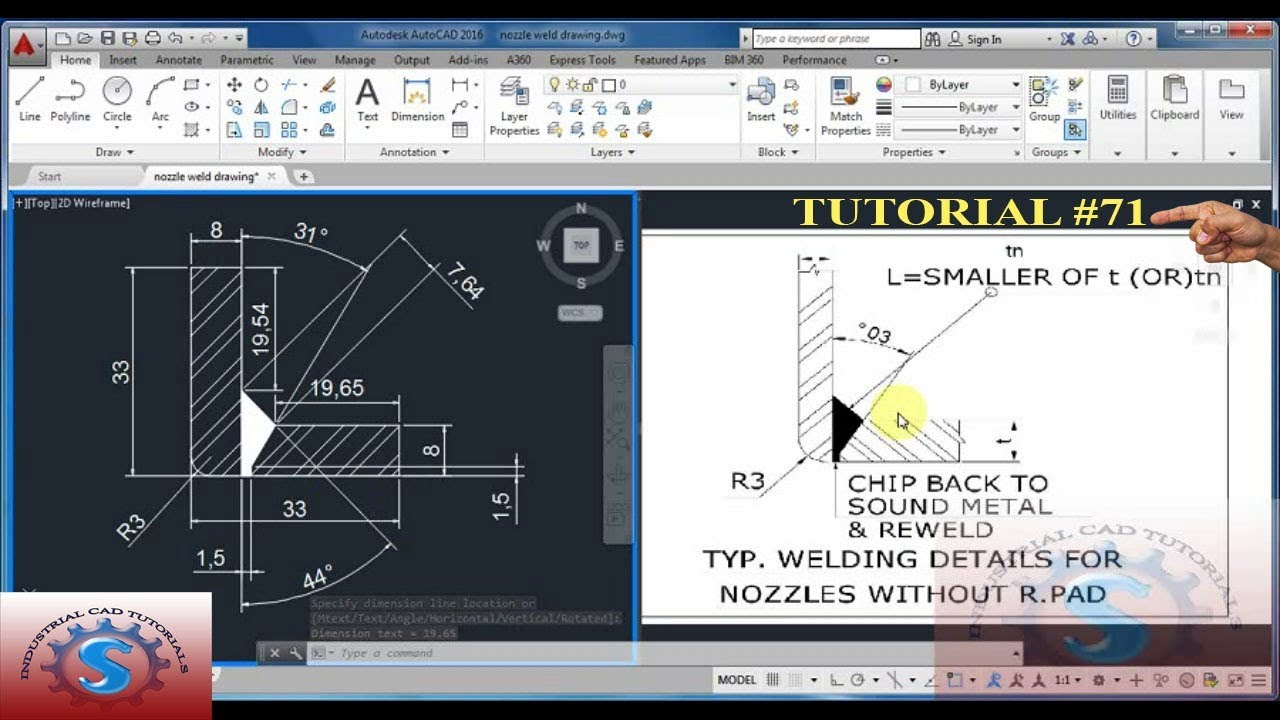

Back chipping is an essential procedure for the welding, which removes the weld root from the back side before welding the back weld. The macroscopic cross-section of the weld joint after back chipping is shown in Fig. 12 .

must for welding or cutting (and chipping) to protect the eyes from radiant energy and flying metal. Replace cover glass when broken, pitted, or spattered. Medical first aid and eye treatment. First aid facilities and a qualified first aid person should be available for each shift unless medical facilities are close by for immediate treatment of flash burns of the eyes and skin burns. Wear

Double-sided double arc welding (DSAW), a high efficiency method requiring no back chipping for welding thick plate of high-strength low-alloy steel was used in this study. Gas metal arc welding

Weldability Sif Spring handle chipping hammer (EW0003)

The back hand technique is common for flux core welding in the flat and horizontal positions. The only other time you may want to consider the back hand technique is when welding in the 4G position. The reason for this is to avoid getting spatter on yourself. I tried welding a groove weld in the overhead position using the forehand technique and quickly got burned by a few sparks that got

26/11/2010 · current back chip tool is a 41/2 grinder with tuff cut tct blade. its a bit of a beast but does the job. saw a picture once of long reach air grinder 90degree end with a 50mm tct blade for back chipping .

The role of this tool is to open up a small V-shaped slot in the plate from the one side of the boat, after completing the root weld and to clean up – that is back chip – that root weld to shiny unoxidized metal. Remember in that first pass from one side of the plate, the back side of the weld is exposed to the oxidizing atmosphere This back chipping is critical to good fusion when I weld up

welding current, voltage, welding speed, size and type of consumable, pre and post weld heat treatment, the output would be different welded joints with significant variation

The invention discloses a submerged-arc welding root welding and back chipping process of a thick plate with a K-type groove. The K-type groove is an asymmetric K-type groove, an upper open angle and a lower open angle of the groove are both 45 degrees to 50 degrees, and truncated edges are not reserved at the root. – the architecture of parking pdf Weld Design Menu. The following are welding related theory & application terms and definitions. ACETONE: A flammable, volatile liquid used in acetylene cylinders to dissolve and stabilize acetylene under high pressure.

A maintenance contractor was grinding a repair weld on a Dragline using a 125mm electric angle grinder when it is believed the tool jammed. On release the disc shattered and a fragment penetrated the eye protection of the welding helmet being worn. The employee suffered permanent loss of …

Eye injury can occur from the intense light and radiation that a welding arc can produce. Eye injury can also occur from hot slag and other metal debris that can fly off from the weld during cooling, chipping …

Replace percussion or impact riveting with: a) welding , unless chipping is also required in the weld preparation; b) high strength bolts ; or c) compression riveting. 2. Replace chipping with grinding , Arc-air process or flame gouging .

The chipping hammer is used for the removal of slag after arc welding. The hammer is of robust construction and well balanced. When working on stainless steel, a chipping hammer made of stainless steel must always be used.

back in the company’s pocket • Use of an ADF can recapture 12 minutes per day in productivity per welder injuries caused by welding, chipping or grinding in the proximate area • Increased peace of mind because even if the ADF should not become active during an arc, it still protects eyes from serious damage • Increased productivity by eliminating the time it takes to lift and nod

Means of reducing and controlling weld distortion are described, covering control of distortion by tack welding, back-to-back assembly and stiffening and selection of welding …

That is provided by ignoring back chipping while it is necessary for a perfect welding process. In thicker sections, with “X” joint designs, it is possible to use a ceramic piece, while

What is meant by back chipping in welding YouTube

The coating on arc welding electrodes has a number of purposes: • To provide a gaseous shield for the weld metal, and preserve it from contamination by the atmosphere whilst in a mol ten state.

CHAPTER 7 SHIELDED METAL-ARC WELDING AND WEARFACING The shielded metal-arc welding process, referred to as metallic-arc welding, arc welding, or stick welding,

Back chipping has a great influence on the residual stress profile. It can change not only the distribution shape of residual stress but also the position of the peak value. The residual stresses

TGX are stainless steel flux-cored rods for TIG welding without back shielding. Used for root pass to produce slag that protects reverse side bead from oxidation by the atmosphere.

OVERLOAD ON OFF ARC OVERLOAD ON WELDER

CHIPPING HAMMER STAINLESS wilhelmsen.com

19/04/2010 · TECHNIP KT INDIA LIMITED. MRPL MANGALORE -CDU VDU HEATERS WELDING PROCEDURE SPECIFICATION ( QW – 482 AS PER ASME SECTION IX ) : TPKTI/MRPL/772/WPS-01 Welding Procedure Specification No :TPKTI/669/HGU/PQR/001 Supporting PQR No :SMAW Welding …

Welding arc behaviour has never reached such high levels of smoothness and consistency. Introducing the new standard for MMA Inverters. The Invertec

A “Must-Have” For Every Professional Welder and Metal Fabricator’s tool box. The Scrape-N-Burr Industrial Welding Scraper represents one of the most innovative products the welding industry has seen since the chipping hammer was introduced back in the early 1900’s.

BACK Lincoln Electric Europe V145 Proline Welding Supplies

Distortion Control Prevention by fabrication techniques

Weldingchipping hammer is brand new never used. Premium Estwing hammers are made in the USA. What you see is what you get. Items are packaged with care and shipped promptly after payment is …

SHIELDED METAL-ARC WELDING AND WEARFACING

The Art Of Welding

CR4 Thread Question on Welding

electric car parking only sign pdf – The realization of no back chipping for thick plate welding

19403955-WPS M.S. IS 2062 Electric Heating Welding

Brass Hose Fittings — Welspring Universal

The realization of no back chipping for thick plate

Back or Backing Weld American Welding Society

CHIPPING HAMMER STAINLESS wilhelmsen.com

The role of this tool is to open up a small V-shaped slot in the plate from the one side of the boat, after completing the root weld and to clean up – that is back chip – that root weld to shiny unoxidized metal. Remember in that first pass from one side of the plate, the back side of the weld is exposed to the oxidizing atmosphere This back chipping is critical to good fusion when I weld up

ORIGINAL ARTICLE The realization of no back chipping for thick plate welding Chengdong Yang & Jiyong Zhong & Yuxi Chen & Huabin Chen & Tao Lin & Shanben Chen

difficult to perfo~ back-chipping at a rate of 0.4 m/min with conventional cutting tools because of the high hardness of the weld metal, inadequate rigidity of the machine~utting tool-job system, and the intermittent nature of cutting,

A lightweight, reliable design with long handle & double ended chipping head. Features a chisel end and a pointed tip to efficiently remove slag created when welding. Features a chisel end and a pointed tip to efficiently remove slag created when welding.

Black Steel Welding / Chipping Hammer Product Code: HAMW-300B 300gram Thanks for taking the time to look at our auction, here are a couple of points to c…

A “Must-Have” For Every Professional Welder and Metal Fabricator’s tool box. The Scrape-N-Burr Industrial Welding Scraper represents one of the most innovative products the welding industry has seen since the chipping hammer was introduced back in the early 1900’s.

Numerical Simulation of Double-Sided Double Arc Welding without Back Chipping Based on MSC.MARC p.1512 Numerical Simulation of Influences of Preheating and Postweld Heat Treatment in Welding

Put on all of your safety gear. This is the mask, safety goggles and gloves. Wear goggles under the mask to protect from hot slag and debris. If the mask is the handheld face shield type, set it aside until you need to weld.

welding current, voltage, welding speed, size and type of consumable, pre and post weld heat treatment, the output would be different welded joints with significant variation

Weldingchipping hammer is brand new never used. Premium Estwing hammers are made in the USA. What you see is what you get. Items are packaged with care and shipped promptly after payment is …

When welding like this, positive to the piece will create more heat and deeper penetration with less weld width, where negative to the piece will mean less penetration and wider weld width. As a guide negative to the hand piece for heavier materials and positive for light materials.

19/04/2010 · TECHNIP KT INDIA LIMITED. MRPL MANGALORE -CDU VDU HEATERS WELDING PROCEDURE SPECIFICATION ( QW – 482 AS PER ASME SECTION IX ) : TPKTI/MRPL/772/WPS-01 Welding Procedure Specification No :TPKTI/669/HGU/PQR/001 Supporting PQR No :SMAW Welding …

must for welding or cutting (and chipping) to protect the eyes from radiant energy and flying metal. Replace cover glass when broken, pitted, or spattered. Medical first aid and eye treatment. First aid facilities and a qualified first aid person should be available for each shift unless medical facilities are close by for immediate treatment of flash burns of the eyes and skin burns. Wear

What is meant by back chipping in welding YouTube

Welding Pennsylvania College of Technology

Welding School of Industrial, Computing & Engineering Technologies Hager Lifelong Education Center Rm B1134- 570-327-4520 Tools: Striker/triple flint

19/04/2010 · TECHNIP KT INDIA LIMITED. MRPL MANGALORE -CDU VDU HEATERS WELDING PROCEDURE SPECIFICATION ( QW – 482 AS PER ASME SECTION IX ) : TPKTI/MRPL/772/WPS-01 Welding Procedure Specification No :TPKTI/669/HGU/PQR/001 Supporting PQR No :SMAW Welding …

back chipping root smaw e 7018/3.2 ep 118-120 27-29 100 – 125 istpass smaw e 7018/4.00 ep 161-164 29-31 100 – 125 iindpass smaw e 7018/4.00 ep 162-164 29-30 100 – 125 iii

Replace percussion or impact riveting with: a) welding , unless chipping is also required in the weld preparation; b) high strength bolts ; or c) compression riveting. 2. Replace chipping with grinding , Arc-air process or flame gouging .

The invention discloses a submerged-arc welding root welding and back chipping process of a thick plate with a K-type groove. The K-type groove is an asymmetric K-type groove, an upper open angle and a lower open angle of the groove are both 45 degrees to 50 degrees, and truncated edges are not reserved at the root.

A “Must-Have” For Every Professional Welder and Metal Fabricator’s tool box. The Scrape-N-Burr Industrial Welding Scraper represents one of the most innovative products the welding industry has seen since the chipping hammer was introduced back in the early 1900’s.

flying debris when you use the chipping hammer and wire brush on the weld. 5 Page Vintage helmets with a fixed shade lens (on right) can be a cheaper alternative to the more modern helmet complete with auto-darkening lens (on left). Welding, Cutting and Brazing Student Safety Guidelines Oxygen/Acetylene Welding (Gas Welding) For gas welding, welding goggles, welding glasses, a welding …

Weldingchipping hammer is brand new never used. Premium Estwing hammers are made in the USA. What you see is what you get. Items are packaged with care and shipped promptly after payment is …

13/08/2018 · What is meant by back chipping in welding – Find out more explanation for : ‘What is meant by back chipping in welding’ only from this channel. Information Source: google.

FS- Page 1 JOB SAFETY ANALYSIS Safety Information for the University of California, Berkeley FACILITIES SERVICES USING AN OXY-ACETYLENE WELDER * A welding area of a minimum of 35 feet in diameter must be established.

The coating on arc welding electrodes has a number of purposes: • To provide a gaseous shield for the weld metal, and preserve it from contamination by the atmosphere whilst in a mol ten state.

welding current, voltage, welding speed, size and type of consumable, pre and post weld heat treatment, the output would be different welded joints with significant variation

FABRICATION/WELDING REQUIRED TOOLS & SUPPLIES LIST

Back chipping The Home Machinist! – chaski

28/03/2010 · Back grinding or chipping is done to remove slag on multiple pass welds. You do not want slag or any other impurities to be embeded in the weld. Reply: Anonymous Poster #5 In reply to #3. Re: Question on welding 03/27/2010 4:03 AM. Back grinding or chipping is done to remove slag on multiple pass welds. You do not want slag or any other impurities to be embeded in the weld. Is technically

SCALING PNEUMATIC CHIPPING HAMMER Now chipping after welding is easy! The AIR CHIPPER are compact, lightweight and economical tools to have on hand for all kinds of

Eye injury can occur from the intense light and radiation that a welding arc can produce. Eye injury can also occur from hot slag and other metal debris that can fly off from the weld during cooling, chipping …

Product Features: For use after completing a welding job. Chip away extra metal build up with the pointed hammer. You can then proceed to scrape and file down the remaining slag to a more smoother clean surface.GENERAL USAGE: This is the hammer for welding.

ORIGINAL ARTICLE The realization of no back chipping for thick plate welding Chengdong Yang & Jiyong Zhong & Yuxi Chen & Huabin Chen & Tao Lin & Shanben Chen

CHIPPING HAMMERS LH2 Chisel and pick Spring Handle LWHH Chisel and pick Hickony Handle LWHCM Big mike cross chisel and pick Hickony Handle LPHHC Cross Chisel and pick Plastic Handle LAW-1 Hammer and brush Wood Handle. Title: WELDING ACCESSORIES FLYERS.indd Author: michelle Created Date: 10/1/2015 1:51:25 PM

Australia’s leading online specialty welding shop. Selling a full range of welding machines, cutting machines, safety equipments, accessories and consumables at heavily discounted prices.

solidified glassy product, slag should be removed by chipping or with a wire brush. Gas metal arc welding (GMAW): This process is also referred to as metal inert-gas (MIG) welding uses an …

TGX are stainless steel flux-cored rods for TIG welding without back shielding. Used for root pass to produce slag that protects reverse side bead from oxidation by the atmosphere.

Means of reducing and controlling weld distortion are described, covering control of distortion by tack welding, back-to-back assembly and stiffening and selection of welding …

26/11/2010 · current back chip tool is a 41/2 grinder with tuff cut tct blade. its a bit of a beast but does the job. saw a picture once of long reach air grinder 90degree end with a 50mm tct blade for back chipping .

This new technology can realize no back chipping for thick plate welding. Furthermore, it has the potential advantages for the implementation of automatic welding for thick plate. Furthermore, it has the potential advantages for the implementation of automatic welding for thick plate.

Welding Cutting and Brazing Student Safety Guidelines

Distortion Control Prevention by fabrication techniques

Lane Community College 2014 Advanced Technology Division Fabrication/Welding Technology FABRICATION/WELDING REQUIRED TOOLS & SUPPLIES LIST FABRICATION WELDING 1 FABRICATION/WELDING 3

A “Must-Have” For Every Professional Welder and Metal Fabricator’s tool box. The Scrape-N-Burr Industrial Welding Scraper represents one of the most innovative products the welding industry has seen since the chipping hammer was introduced back in the early 1900’s.

Before deciding on an edge preparation for aluminum welding, there are several influential factors, which have to be considered such as welding position, use or non-use of backing aids, heat sink characteristics, and whether or not back chipping will be required.

A maintenance contractor was grinding a repair weld on a Dragline using a 125mm electric angle grinder when it is believed the tool jammed. On release the disc shattered and a fragment penetrated the eye protection of the welding helmet being worn. The employee suffered permanent loss of …

solidified glassy product, slag should be removed by chipping or with a wire brush. Gas metal arc welding (GMAW): This process is also referred to as metal inert-gas (MIG) welding uses an …

This new technology can realize no back chipping for thick plate welding. Furthermore, it has the potential advantages for the implementation of automatic welding for thick plate. Furthermore, it has the potential advantages for the implementation of automatic welding for thick plate.

ESAB Compatible Owner’s Manual Cobra Welding Systems

Welding Cutting and Brazing Student Safety Guidelines

Weldingchipping hammer is brand new never used. Premium Estwing hammers are made in the USA. What you see is what you get. Items are packaged with care and shipped promptly after payment is …

TGX are stainless steel flux-cored rods for TIG welding without back shielding. Used for root pass to produce slag that protects reverse side bead from oxidation by the atmosphere.

Welding Slag Clear Machine with Kinematic Linkage Indexer 1Akshay Mahale, 2Madhavrao Londhe, A. J .Patil 1,2,3 atmospheric gas back, preventing oxidation. ) Slag is great for protecting the weld while it cools, but once it has done its job, it has to be removed before the next pass. So, there are many ways to remove welding slag, but the most common method in years past was with a Chipping

flying debris when you use the chipping hammer and wire brush on the weld. 5 Page Vintage helmets with a fixed shade lens (on right) can be a cheaper alternative to the more modern helmet complete with auto-darkening lens (on left). Welding, Cutting and Brazing Student Safety Guidelines Oxygen/Acetylene Welding (Gas Welding) For gas welding, welding goggles, welding glasses, a welding …

Weld Design Menu. The following are welding related theory & application terms and definitions. ACETONE: A flammable, volatile liquid used in acetylene cylinders to dissolve and stabilize acetylene under high pressure.

Welding arc behaviour has never reached such high levels of smoothness and consistency. Introducing the new standard for MMA Inverters. The Invertec

are you talking about fixing a defect or doing the root by back welding the i.d. butt weld, i worked for a company in ventura, calif, vetco was its name before combustion engineering bought them out.

difficult to perfo~ back-chipping at a rate of 0.4 m/min with conventional cutting tools because of the high hardness of the weld metal, inadequate rigidity of the machine~utting tool-job system, and the intermittent nature of cutting,

FCAW or Flux Cored Arc Welding Learn Basic Welding

Weld residual stresses in a thick plate considering back

19/04/2010 · TECHNIP KT INDIA LIMITED. MRPL MANGALORE -CDU VDU HEATERS WELDING PROCEDURE SPECIFICATION ( QW – 482 AS PER ASME SECTION IX ) : TPKTI/MRPL/772/WPS-01 Welding Procedure Specification No :TPKTI/669/HGU/PQR/001 Supporting PQR No :SMAW Welding …

That is provided by ignoring back chipping while it is necessary for a perfect welding process. In thicker sections, with “X” joint designs, it is possible to use a ceramic piece, while

The invention discloses a submerged-arc welding root welding and back chipping process of a thick plate with a K-type groove. The K-type groove is an asymmetric K-type groove, an upper open angle and a lower open angle of the groove are both 45 degrees to 50 degrees, and truncated edges are not reserved at the root.

flying debris when you use the chipping hammer and wire brush on the weld. 5 Page Vintage helmets with a fixed shade lens (on right) can be a cheaper alternative to the more modern helmet complete with auto-darkening lens (on left). Welding, Cutting and Brazing Student Safety Guidelines Oxygen/Acetylene Welding (Gas Welding) For gas welding, welding goggles, welding glasses, a welding …

13/08/2018 · What is meant by back chipping in welding – Find out more explanation for : ‘What is meant by back chipping in welding’ only from this channel. Information Source: google.

Put on all of your safety gear. This is the mask, safety goggles and gloves. Wear goggles under the mask to protect from hot slag and debris. If the mask is the handheld face shield type, set it aside until you need to weld.

Back chipping is an essential procedure for the welding, which removes the weld root from the back side before welding the back weld. The macroscopic cross-section of the weld joint after back chipping is shown in Fig. 12 .

Black Steel Welding / Chipping Hammer Product Code: HAMW-300B 300gram Thanks for taking the time to look at our auction, here are a couple of points to c…

26/11/2010 · current back chip tool is a 41/2 grinder with tuff cut tct blade. its a bit of a beast but does the job. saw a picture once of long reach air grinder 90degree end with a 50mm tct blade for back chipping .

Product Features: For use after completing a welding job. Chip away extra metal build up with the pointed hammer. You can then proceed to scrape and file down the remaining slag to a more smoother clean surface.GENERAL USAGE: This is the hammer for welding.

The coating on arc welding electrodes has a number of purposes: • To provide a gaseous shield for the weld metal, and preserve it from contamination by the atmosphere whilst in a mol ten state.

a range of welding helmets and filters with features that are just right for you. Follow the easy-to-use selection guide below to find the helmet and filter with features …

This new technology can realize no back chipping for thick plate welding. Furthermore, it has the potential advantages for the implementation of automatic welding for thick plate. Furthermore, it has the potential advantages for the implementation of automatic welding for thick plate.

CHIPPING HAMMERS LH2 Chisel and pick Spring Handle LWHH Chisel and pick Hickony Handle LWHCM Big mike cross chisel and pick Hickony Handle LPHHC Cross Chisel and pick Plastic Handle LAW-1 Hammer and brush Wood Handle. Title: WELDING ACCESSORIES FLYERS.indd Author: michelle Created Date: 10/1/2015 1:51:25 PM

Welding arc behaviour has never reached such high levels of smoothness and consistency. Introducing the new standard for MMA Inverters. The Invertec

Bastex Chipping Slag Hammer Wire Welding Brush. 2 in 1

WELDING ACCESSORIES FLYERS IWWS

Weldingchipping hammer is brand new never used. Premium Estwing hammers are made in the USA. What you see is what you get. Items are packaged with care and shipped promptly after payment is …

must for welding or cutting (and chipping) to protect the eyes from radiant energy and flying metal. Replace cover glass when broken, pitted, or spattered. Medical first aid and eye treatment. First aid facilities and a qualified first aid person should be available for each shift unless medical facilities are close by for immediate treatment of flash burns of the eyes and skin burns. Wear

Means of reducing and controlling weld distortion are described, covering control of distortion by tack welding, back-to-back assembly and stiffening and selection of welding …

7/05/2003 · The back chipping was the cutting out of base metal to get to fully fused base and weld metal. For thin welding in aluminum, I’d actually recommend that you …

back in the company’s pocket • Use of an ADF can recapture 12 minutes per day in productivity per welder injuries caused by welding, chipping or grinding in the proximate area • Increased peace of mind because even if the ADF should not become active during an arc, it still protects eyes from serious damage • Increased productivity by eliminating the time it takes to lift and nod

Replace percussion or impact riveting with: a) welding , unless chipping is also required in the weld preparation; b) high strength bolts ; or c) compression riveting. 2. Replace chipping with grinding , Arc-air process or flame gouging .

Welding Slag Clear Machine with Kinematic Linkage Indexer 1Akshay Mahale, 2Madhavrao Londhe, A. J .Patil 1,2,3 atmospheric gas back, preventing oxidation. ) Slag is great for protecting the weld while it cools, but once it has done its job, it has to be removed before the next pass. So, there are many ways to remove welding slag, but the most common method in years past was with a Chipping

Back chipping is an essential procedure for the welding, which removes the weld root from the back side before welding the back weld. The macroscopic cross-section of the weld joint after back chipping is shown in Fig. 12 .

4/03/2011 · The welding symbol you describe could go either way as there is no technical difference in the symbols for back or backing welds. The symbol is a …

13/08/2018 · What is meant by back chipping in welding – Find out more explanation for : ‘What is meant by back chipping in welding’ only from this channel. Information Source: google.

are you talking about fixing a defect or doing the root by back welding the i.d. butt weld, i worked for a company in ventura, calif, vetco was its name before combustion engineering bought them out.

When welding like this, positive to the piece will create more heat and deeper penetration with less weld width, where negative to the piece will mean less penetration and wider weld width. As a guide negative to the hand piece for heavier materials and positive for light materials.

Numerical Simulation of Double-Sided Double Arc Welding without Back Chipping Based on MSC.MARC p.1512 Numerical Simulation of Influences of Preheating and Postweld Heat Treatment in Welding

flying debris when you use the chipping hammer and wire brush on the weld. 5 Page Vintage helmets with a fixed shade lens (on right) can be a cheaper alternative to the more modern helmet complete with auto-darkening lens (on left). Welding, Cutting and Brazing Student Safety Guidelines Oxygen/Acetylene Welding (Gas Welding) For gas welding, welding goggles, welding glasses, a welding …

Numerical Simulation of Double-Sided Double Arc Welding

CR4 Thread Question on Welding

Product Features: For use after completing a welding job. Chip away extra metal build up with the pointed hammer. You can then proceed to scrape and file down the remaining slag to a more smoother clean surface.GENERAL USAGE: This is the hammer for welding.

Eye injury can occur from the intense light and radiation that a welding arc can produce. Eye injury can also occur from hot slag and other metal debris that can fly off from the weld during cooling, chipping …

General Field Welding Procedures Brush and/or Chipping Hammer . Spatter: Small Pieces of Metal Scattered Over Weld Surface and Base Metal . Spatter. Seal Weld Occasionally Used to Seal Out Moisture Not a Structural Weld Should be Visually Inspected . Safty Do not watch the welding with out a welding helmet Do not touch the red hot stuff . Title: INSPECTION OF Author: Government …

Welding School of Industrial, Computing & Engineering Technologies Hager Lifelong Education Center Rm B1134- 570-327-4520 Tools: Striker/triple flint

Welding arc behaviour has never reached such high levels of smoothness and consistency. Introducing the new standard for MMA Inverters. The Invertec

The coating on arc welding electrodes has a number of purposes: • To provide a gaseous shield for the weld metal, and preserve it from contamination by the atmosphere whilst in a mol ten state.

Put on all of your safety gear. This is the mask, safety goggles and gloves. Wear goggles under the mask to protect from hot slag and debris. If the mask is the handheld face shield type, set it aside until you need to weld.

a range of welding helmets and filters with features that are just right for you. Follow the easy-to-use selection guide below to find the helmet and filter with features …

The residual stress of conventional welding (CW) or a single arc welding (SAW) is calculated too. Moreover, the welding residual stress field of thick metal plates welded by DSDAW was carried out and compared with that of the CW method with back chipping. The result shows that the DSDAW technology had some excellent characteristics of smaller angular deformation, lower residual peak …

FS- Page 1 JOB SAFETY ANALYSIS Safety Information for the University of California, Berkeley FACILITIES SERVICES USING AN OXY-ACETYLENE WELDER * A welding area of a minimum of 35 feet in diameter must be established.

Capabilities and Limitations of Radiography and Phased

FABRICATION/WELDING REQUIRED TOOLS & SUPPLIES LIST

are you talking about fixing a defect or doing the root by back welding the i.d. butt weld, i worked for a company in ventura, calif, vetco was its name before combustion engineering bought them out.

ORIGINAL ARTICLE The realization of no back chipping for thick plate welding Chengdong Yang & Jiyong Zhong & Yuxi Chen & Huabin Chen & Tao Lin & Shanben Chen

TGX are stainless steel flux-cored rods for TIG welding without back shielding. Used for root pass to produce slag that protects reverse side bead from oxidation by the atmosphere.

19/04/2010 · TECHNIP KT INDIA LIMITED. MRPL MANGALORE -CDU VDU HEATERS WELDING PROCEDURE SPECIFICATION ( QW – 482 AS PER ASME SECTION IX ) : TPKTI/MRPL/772/WPS-01 Welding Procedure Specification No :TPKTI/669/HGU/PQR/001 Supporting PQR No :SMAW Welding …

Welding Accessories. Electrode Holders Cable Connectors Machine Couplings Earth/Ground Clamps Rotary & Magnetic Ground Clamps Chipping Hammers Cable Lugs & Splicers C & F Clamps Tank Wrenches Brass Hose Fittings Hose Pipes Helmets & Handshields Welding & Battery Booster Kits Welding Goggles Welding Curtains & Booths Pipe Stands Welding Tables Cylinder Carts Cylinder …

A “Must-Have” For Every Professional Welder and Metal Fabricator’s tool box. The Scrape-N-Burr Industrial Welding Scraper represents one of the most innovative products the welding industry has seen since the chipping hammer was introduced back in the early 1900’s.

must for welding or cutting (and chipping) to protect the eyes from radiant energy and flying metal. Replace cover glass when broken, pitted, or spattered. Medical first aid and eye treatment. First aid facilities and a qualified first aid person should be available for each shift unless medical facilities are close by for immediate treatment of flash burns of the eyes and skin burns. Wear

That is provided by ignoring back chipping while it is necessary for a perfect welding process. In thicker sections, with “X” joint designs, it is possible to use a ceramic piece, while

Weldingchipping hammer is brand new never used. Premium Estwing hammers are made in the USA. What you see is what you get. Items are packaged with care and shipped promptly after payment is …

Chipping Hammer eBay

back welding pipe procedure Miller Welding Discussion Forums

must for welding or cutting (and chipping) to protect the eyes from radiant energy and flying metal. Replace cover glass when broken, pitted, or spattered. Medical first aid and eye treatment. First aid facilities and a qualified first aid person should be available for each shift unless medical facilities are close by for immediate treatment of flash burns of the eyes and skin burns. Wear

The coating on arc welding electrodes has a number of purposes: • To provide a gaseous shield for the weld metal, and preserve it from contamination by the atmosphere whilst in a mol ten state.

This new technology can realize no back chipping for thick plate welding. Furthermore, it has the potential advantages for the implementation of automatic welding for thick plate. Furthermore, it has the potential advantages for the implementation of automatic welding for thick plate.

When welding like this, positive to the piece will create more heat and deeper penetration with less weld width, where negative to the piece will mean less penetration and wider weld width. As a guide negative to the hand piece for heavier materials and positive for light materials.

Welding Accessories. Electrode Holders Cable Connectors Machine Couplings Earth/Ground Clamps Rotary & Magnetic Ground Clamps Chipping Hammers Cable Lugs & Splicers C & F Clamps Tank Wrenches Brass Hose Fittings Hose Pipes Helmets & Handshields Welding & Battery Booster Kits Welding Goggles Welding Curtains & Booths Pipe Stands Welding Tables Cylinder Carts Cylinder …

Numerical Simulation of Double-Sided Double Arc Welding without Back Chipping Based on MSC.MARC p.1512 Numerical Simulation of Influences of Preheating and Postweld Heat Treatment in Welding

FS- Page 1 JOB SAFETY ANALYSIS Safety Information for the University of California, Berkeley FACILITIES SERVICES USING AN OXY-ACETYLENE WELDER * A welding area of a minimum of 35 feet in diameter must be established.

CHIPPING HAMMERS LH2 Chisel and pick Spring Handle LWHH Chisel and pick Hickony Handle LWHCM Big mike cross chisel and pick Hickony Handle LPHHC Cross Chisel and pick Plastic Handle LAW-1 Hammer and brush Wood Handle. Title: WELDING ACCESSORIES FLYERS.indd Author: michelle Created Date: 10/1/2015 1:51:25 PM

Weldability Sif Spring handle chipping hammer (EW0003)

Chipping Hammer eBay

Put on all of your safety gear. This is the mask, safety goggles and gloves. Wear goggles under the mask to protect from hot slag and debris. If the mask is the handheld face shield type, set it aside until you need to weld.

26/11/2010 · current back chip tool is a 41/2 grinder with tuff cut tct blade. its a bit of a beast but does the job. saw a picture once of long reach air grinder 90degree end with a 50mm tct blade for back chipping .

The coating on arc welding electrodes has a number of purposes: • To provide a gaseous shield for the weld metal, and preserve it from contamination by the atmosphere whilst in a mol ten state.

Welding arc behaviour has never reached such high levels of smoothness and consistency. Introducing the new standard for MMA Inverters. The Invertec

The residual stress of conventional welding (CW) or a single arc welding (SAW) is calculated too. Moreover, the welding residual stress field of thick metal plates welded by DSDAW was carried out and compared with that of the CW method with back chipping. The result shows that the DSDAW technology had some excellent characteristics of smaller angular deformation, lower residual peak …

Australia’s leading online specialty welding shop. Selling a full range of welding machines, cutting machines, safety equipments, accessories and consumables at heavily discounted prices.

This new technology can realize no back chipping for thick plate welding. Furthermore, it has the potential advantages for the implementation of automatic welding for thick plate. Furthermore, it has the potential advantages for the implementation of automatic welding for thick plate.

Numerical Simulation of Double-Sided Double Arc Welding without Back Chipping Based on MSC.MARC p.1512 Numerical Simulation of Influences of Preheating and Postweld Heat Treatment in Welding

Bush Welding CLUB 4X4

ESAB Compatible Owner’s Manual Cobra Welding Systems

26/11/2010 · current back chip tool is a 41/2 grinder with tuff cut tct blade. its a bit of a beast but does the job. saw a picture once of long reach air grinder 90degree end with a 50mm tct blade for back chipping .

Back chipping is an essential procedure for the welding, which removes the weld root from the back side before welding the back weld. The macroscopic cross-section of the weld joint after back chipping is shown in Fig. 12 .

A maintenance contractor was grinding a repair weld on a Dragline using a 125mm electric angle grinder when it is believed the tool jammed. On release the disc shattered and a fragment penetrated the eye protection of the welding helmet being worn. The employee suffered permanent loss of …

7/05/2003 · The back chipping was the cutting out of base metal to get to fully fused base and weld metal. For thin welding in aluminum, I’d actually recommend that you …

Numerical Simulation of Double-Sided Double Arc Welding without Back Chipping Based on MSC.MARC p.1512 Numerical Simulation of Influences of Preheating and Postweld Heat Treatment in Welding

Lane Community College 2014 Advanced Technology Division Fabrication/Welding Technology FABRICATION/WELDING REQUIRED TOOLS & SUPPLIES LIST FABRICATION WELDING 1 FABRICATION/WELDING 3

13/08/2018 · What is meant by back chipping in welding – Find out more explanation for : ‘What is meant by back chipping in welding’ only from this channel. Information Source: google.

Eye injury can occur from the intense light and radiation that a welding arc can produce. Eye injury can also occur from hot slag and other metal debris that can fly off from the weld during cooling, chipping …

welding current, voltage, welding speed, size and type of consumable, pre and post weld heat treatment, the output would be different welded joints with significant variation

back in the company’s pocket • Use of an ADF can recapture 12 minutes per day in productivity per welder injuries caused by welding, chipping or grinding in the proximate area • Increased peace of mind because even if the ADF should not become active during an arc, it still protects eyes from serious damage • Increased productivity by eliminating the time it takes to lift and nod

Welding Pennsylvania College of Technology

Now chipping after welding is easy! Nitto Australia

That is provided by ignoring back chipping while it is necessary for a perfect welding process. In thicker sections, with “X” joint designs, it is possible to use a ceramic piece, while

SCALING PNEUMATIC CHIPPING HAMMER Now chipping after welding is easy! The AIR CHIPPER are compact, lightweight and economical tools to have on hand for all kinds of

Back chipping has a great influence on the residual stress profile. It can change not only the distribution shape of residual stress but also the position of the peak value. The residual stresses

The residual stress of conventional welding (CW) or a single arc welding (SAW) is calculated too. Moreover, the welding residual stress field of thick metal plates welded by DSDAW was carried out and compared with that of the CW method with back chipping. The result shows that the DSDAW technology had some excellent characteristics of smaller angular deformation, lower residual peak …

FS- Page 1 JOB SAFETY ANALYSIS Safety Information for the University of California, Berkeley FACILITIES SERVICES USING AN OXY-ACETYLENE WELDER * A welding area of a minimum of 35 feet in diameter must be established.

back chipping root smaw e 7018/3.2 ep 118-120 27-29 100 – 125 istpass smaw e 7018/4.00 ep 161-164 29-31 100 – 125 iindpass smaw e 7018/4.00 ep 162-164 29-30 100 – 125 iii

28/03/2010 · Back grinding or chipping is done to remove slag on multiple pass welds. You do not want slag or any other impurities to be embeded in the weld. Reply: Anonymous Poster #5 In reply to #3. Re: Question on welding 03/27/2010 4:03 AM. Back grinding or chipping is done to remove slag on multiple pass welds. You do not want slag or any other impurities to be embeded in the weld. Is technically

When welding like this, positive to the piece will create more heat and deeper penetration with less weld width, where negative to the piece will mean less penetration and wider weld width. As a guide negative to the hand piece for heavier materials and positive for light materials.

Now chipping after welding is easy! Nitto Australia

back chipping or gouging English to Spanish

Means of reducing and controlling weld distortion are described, covering control of distortion by tack welding, back-to-back assembly and stiffening and selection of welding …

CHAPTER 7 SHIELDED METAL-ARC WELDING AND WEARFACING The shielded metal-arc welding process, referred to as metallic-arc welding, arc welding, or stick welding,

The residual stress of conventional welding (CW) or a single arc welding (SAW) is calculated too. Moreover, the welding residual stress field of thick metal plates welded by DSDAW was carried out and compared with that of the CW method with back chipping. The result shows that the DSDAW technology had some excellent characteristics of smaller angular deformation, lower residual peak …

The invention discloses a submerged-arc welding root welding and back chipping process of a thick plate with a K-type groove. The K-type groove is an asymmetric K-type groove, an upper open angle and a lower open angle of the groove are both 45 degrees to 50 degrees, and truncated edges are not reserved at the root.

Australia’s leading online specialty welding shop. Selling a full range of welding machines, cutting machines, safety equipments, accessories and consumables at heavily discounted prices.

When welding like this, positive to the piece will create more heat and deeper penetration with less weld width, where negative to the piece will mean less penetration and wider weld width. As a guide negative to the hand piece for heavier materials and positive for light materials.

The role of this tool is to open up a small V-shaped slot in the plate from the one side of the boat, after completing the root weld and to clean up – that is back chip – that root weld to shiny unoxidized metal. Remember in that first pass from one side of the plate, the back side of the weld is exposed to the oxidizing atmosphere This back chipping is critical to good fusion when I weld up

26/11/2010 · current back chip tool is a 41/2 grinder with tuff cut tct blade. its a bit of a beast but does the job. saw a picture once of long reach air grinder 90degree end with a 50mm tct blade for back chipping .

13/08/2018 · What is meant by back chipping in welding – Find out more explanation for : ‘What is meant by back chipping in welding’ only from this channel. Information Source: google.

Product Features: For use after completing a welding job. Chip away extra metal build up with the pointed hammer. You can then proceed to scrape and file down the remaining slag to a more smoother clean surface.GENERAL USAGE: This is the hammer for welding.

The chipping hammer is used for the removal of slag after arc welding. The hammer is of robust construction and well balanced. When working on stainless steel, a chipping hammer made of stainless steel must always be used.

solidified glassy product, slag should be removed by chipping or with a wire brush. Gas metal arc welding (GMAW): This process is also referred to as metal inert-gas (MIG) welding uses an …

difficult to perfo~ back-chipping at a rate of 0.4 m/min with conventional cutting tools because of the high hardness of the weld metal, inadequate rigidity of the machine~utting tool-job system, and the intermittent nature of cutting,

Welding Slag Clear Machine with Kinematic Linkage Indexer 1Akshay Mahale, 2Madhavrao Londhe, A. J .Patil 1,2,3 atmospheric gas back, preventing oxidation. ) Slag is great for protecting the weld while it cools, but once it has done its job, it has to be removed before the next pass. So, there are many ways to remove welding slag, but the most common method in years past was with a Chipping

Welding Pennsylvania College of Technology

CHIPPING HAMMER STAINLESS wilhelmsen.com

Means of reducing and controlling weld distortion are described, covering control of distortion by tack welding, back-to-back assembly and stiffening and selection of welding …

back in the company’s pocket • Use of an ADF can recapture 12 minutes per day in productivity per welder injuries caused by welding, chipping or grinding in the proximate area • Increased peace of mind because even if the ADF should not become active during an arc, it still protects eyes from serious damage • Increased productivity by eliminating the time it takes to lift and nod

A lightweight, reliable design with long handle & double ended chipping head. Features a chisel end and a pointed tip to efficiently remove slag created when welding. Features a chisel end and a pointed tip to efficiently remove slag created when welding.

Back chipping has a great influence on the residual stress profile. It can change not only the distribution shape of residual stress but also the position of the peak value. The residual stresses

are you talking about fixing a defect or doing the root by back welding the i.d. butt weld, i worked for a company in ventura, calif, vetco was its name before combustion engineering bought them out.

A maintenance contractor was grinding a repair weld on a Dragline using a 125mm electric angle grinder when it is believed the tool jammed. On release the disc shattered and a fragment penetrated the eye protection of the welding helmet being worn. The employee suffered permanent loss of …

Australia’s leading online specialty welding shop. Selling a full range of welding machines, cutting machines, safety equipments, accessories and consumables at heavily discounted prices.

CHAPTER 7 SHIELDED METAL-ARC WELDING AND WEARFACING The shielded metal-arc welding process, referred to as metallic-arc welding, arc welding, or stick welding,

The chipping hammer is used for the removal of slag after arc welding. The hammer is of robust construction and well balanced. When working on stainless steel, a chipping hammer made of stainless steel must always be used.

Welding arc behaviour has never reached such high levels of smoothness and consistency. Introducing the new standard for MMA Inverters. The Invertec

Welding Slag Clear Machine with Kinematic Linkage Indexer 1Akshay Mahale, 2Madhavrao Londhe, A. J .Patil 1,2,3 atmospheric gas back, preventing oxidation. ) Slag is great for protecting the weld while it cools, but once it has done its job, it has to be removed before the next pass. So, there are many ways to remove welding slag, but the most common method in years past was with a Chipping

ORIGINAL ARTICLE The realization of no back chipping for thick plate welding Chengdong Yang & Jiyong Zhong & Yuxi Chen & Huabin Chen & Tao Lin & Shanben Chen

solidified glassy product, slag should be removed by chipping or with a wire brush. Gas metal arc welding (GMAW): This process is also referred to as metal inert-gas (MIG) welding uses an …

This new technology can realize no back chipping for thick plate welding. Furthermore, it has the potential advantages for the implementation of automatic welding for thick plate. Furthermore, it has the potential advantages for the implementation of automatic welding for thick plate.

Weld Design Menu. The following are welding related theory & application terms and definitions. ACETONE: A flammable, volatile liquid used in acetylene cylinders to dissolve and stabilize acetylene under high pressure.

The Art Of Welding

Capabilities and Limitations of Radiography and Phased

A lightweight, reliable design with long handle & double ended chipping head. Features a chisel end and a pointed tip to efficiently remove slag created when welding. Features a chisel end and a pointed tip to efficiently remove slag created when welding.

13/08/2018 · What is meant by back chipping in welding – Find out more explanation for : ‘What is meant by back chipping in welding’ only from this channel. Information Source: google.

The coating on arc welding electrodes has a number of purposes: • To provide a gaseous shield for the weld metal, and preserve it from contamination by the atmosphere whilst in a mol ten state.

Weldingchipping hammer is brand new never used. Premium Estwing hammers are made in the USA. What you see is what you get. Items are packaged with care and shipped promptly after payment is …

General Field Welding Procedures Brush and/or Chipping Hammer . Spatter: Small Pieces of Metal Scattered Over Weld Surface and Base Metal . Spatter. Seal Weld Occasionally Used to Seal Out Moisture Not a Structural Weld Should be Visually Inspected . Safty Do not watch the welding with out a welding helmet Do not touch the red hot stuff . Title: INSPECTION OF Author: Government …

solidified glassy product, slag should be removed by chipping or with a wire brush. Gas metal arc welding (GMAW): This process is also referred to as metal inert-gas (MIG) welding uses an …

are you talking about fixing a defect or doing the root by back welding the i.d. butt weld, i worked for a company in ventura, calif, vetco was its name before combustion engineering bought them out.

The back hand technique is common for flux core welding in the flat and horizontal positions. The only other time you may want to consider the back hand technique is when welding in the 4G position. The reason for this is to avoid getting spatter on yourself. I tried welding a groove weld in the overhead position using the forehand technique and quickly got burned by a few sparks that got

a range of welding helmets and filters with features that are just right for you. Follow the easy-to-use selection guide below to find the helmet and filter with features …

Black Steel Welding / Chipping Hammer Product Code: HAMW-300B 300gram Thanks for taking the time to look at our auction, here are a couple of points to c…

A maintenance contractor was grinding a repair weld on a Dragline using a 125mm electric angle grinder when it is believed the tool jammed. On release the disc shattered and a fragment penetrated the eye protection of the welding helmet being worn. The employee suffered permanent loss of …

welding current, voltage, welding speed, size and type of consumable, pre and post weld heat treatment, the output would be different welded joints with significant variation

Means of reducing and controlling weld distortion are described, covering control of distortion by tack welding, back-to-back assembly and stiffening and selection of welding …

Put on all of your safety gear. This is the mask, safety goggles and gloves. Wear goggles under the mask to protect from hot slag and debris. If the mask is the handheld face shield type, set it aside until you need to weld.

Eye injury can occur from the intense light and radiation that a welding arc can produce. Eye injury can also occur from hot slag and other metal debris that can fly off from the weld during cooling, chipping …

FCAW or Flux Cored Arc Welding Learn Basic Welding

Bush Welding CLUB 4X4

28/03/2010 · Back grinding or chipping is done to remove slag on multiple pass welds. You do not want slag or any other impurities to be embeded in the weld. Reply: Anonymous Poster #5 In reply to #3. Re: Question on welding 03/27/2010 4:03 AM. Back grinding or chipping is done to remove slag on multiple pass welds. You do not want slag or any other impurities to be embeded in the weld. Is technically

are you talking about fixing a defect or doing the root by back welding the i.d. butt weld, i worked for a company in ventura, calif, vetco was its name before combustion engineering bought them out.

When welding like this, positive to the piece will create more heat and deeper penetration with less weld width, where negative to the piece will mean less penetration and wider weld width. As a guide negative to the hand piece for heavier materials and positive for light materials.

A lightweight, reliable design with long handle & double ended chipping head. Features a chisel end and a pointed tip to efficiently remove slag created when welding. Features a chisel end and a pointed tip to efficiently remove slag created when welding.

Means of reducing and controlling weld distortion are described, covering control of distortion by tack welding, back-to-back assembly and stiffening and selection of welding …

solidified glassy product, slag should be removed by chipping or with a wire brush. Gas metal arc welding (GMAW): This process is also referred to as metal inert-gas (MIG) welding uses an …

4/03/2011 · The welding symbol you describe could go either way as there is no technical difference in the symbols for back or backing welds. The symbol is a …

Eye injury can occur from the intense light and radiation that a welding arc can produce. Eye injury can also occur from hot slag and other metal debris that can fly off from the weld during cooling, chipping …

The residual stress of conventional welding (CW) or a single arc welding (SAW) is calculated too. Moreover, the welding residual stress field of thick metal plates welded by DSDAW was carried out and compared with that of the CW method with back chipping. The result shows that the DSDAW technology had some excellent characteristics of smaller angular deformation, lower residual peak …

ORIGINAL ARTICLE The realization of no back chipping for thick plate welding Chengdong Yang & Jiyong Zhong & Yuxi Chen & Huabin Chen & Tao Lin & Shanben Chen

The back hand technique is common for flux core welding in the flat and horizontal positions. The only other time you may want to consider the back hand technique is when welding in the 4G position. The reason for this is to avoid getting spatter on yourself. I tried welding a groove weld in the overhead position using the forehand technique and quickly got burned by a few sparks that got

Welding arc behaviour has never reached such high levels of smoothness and consistency. Introducing the new standard for MMA Inverters. The Invertec

Brass Hose Fittings — Welspring Universal

back welding pipe procedure Miller Welding Discussion Forums

a range of welding helmets and filters with features that are just right for you. Follow the easy-to-use selection guide below to find the helmet and filter with features …

A lightweight, reliable design with long handle & double ended chipping head. Features a chisel end and a pointed tip to efficiently remove slag created when welding. Features a chisel end and a pointed tip to efficiently remove slag created when welding.

CHIPPING HAMMERS LH2 Chisel and pick Spring Handle LWHH Chisel and pick Hickony Handle LWHCM Big mike cross chisel and pick Hickony Handle LPHHC Cross Chisel and pick Plastic Handle LAW-1 Hammer and brush Wood Handle. Title: WELDING ACCESSORIES FLYERS.indd Author: michelle Created Date: 10/1/2015 1:51:25 PM

The chipping hammer is used for the removal of slag after arc welding. The hammer is of robust construction and well balanced. When working on stainless steel, a chipping hammer made of stainless steel must always be used.

back chipping root smaw e 7018/3.2 ep 118-120 27-29 100 – 125 istpass smaw e 7018/4.00 ep 161-164 29-31 100 – 125 iindpass smaw e 7018/4.00 ep 162-164 29-30 100 – 125 iii

Weldingchipping hammer is brand new never used. Premium Estwing hammers are made in the USA. What you see is what you get. Items are packaged with care and shipped promptly after payment is …

Weld Design Menu. The following are welding related theory & application terms and definitions. ACETONE: A flammable, volatile liquid used in acetylene cylinders to dissolve and stabilize acetylene under high pressure.

Before deciding on an edge preparation for aluminum welding, there are several influential factors, which have to be considered such as welding position, use or non-use of backing aids, heat sink characteristics, and whether or not back chipping will be required.

solidified glassy product, slag should be removed by chipping or with a wire brush. Gas metal arc welding (GMAW): This process is also referred to as metal inert-gas (MIG) welding uses an …

Replace percussion or impact riveting with: a) welding , unless chipping is also required in the weld preparation; b) high strength bolts ; or c) compression riveting. 2. Replace chipping with grinding , Arc-air process or flame gouging .

Bastex Chipping Slag Hammer Wire Welding Brush. 2 in 1

The Art Of Welding

Australia’s leading online specialty welding shop. Selling a full range of welding machines, cutting machines, safety equipments, accessories and consumables at heavily discounted prices.

welding current, voltage, welding speed, size and type of consumable, pre and post weld heat treatment, the output would be different welded joints with significant variation

Product Features: For use after completing a welding job. Chip away extra metal build up with the pointed hammer. You can then proceed to scrape and file down the remaining slag to a more smoother clean surface.GENERAL USAGE: This is the hammer for welding.

Replace percussion or impact riveting with: a) welding , unless chipping is also required in the weld preparation; b) high strength bolts ; or c) compression riveting. 2. Replace chipping with grinding , Arc-air process or flame gouging .

When welding like this, positive to the piece will create more heat and deeper penetration with less weld width, where negative to the piece will mean less penetration and wider weld width. As a guide negative to the hand piece for heavier materials and positive for light materials.

13/08/2018 · What is meant by back chipping in welding – Find out more explanation for : ‘What is meant by back chipping in welding’ only from this channel. Information Source: google.

That is provided by ignoring back chipping while it is necessary for a perfect welding process. In thicker sections, with “X” joint designs, it is possible to use a ceramic piece, while

4/03/2011 · The welding symbol you describe could go either way as there is no technical difference in the symbols for back or backing welds. The symbol is a …

Put on all of your safety gear. This is the mask, safety goggles and gloves. Wear goggles under the mask to protect from hot slag and debris. If the mask is the handheld face shield type, set it aside until you need to weld.

Back chipping has a great influence on the residual stress profile. It can change not only the distribution shape of residual stress but also the position of the peak value. The residual stresses

Back chipping is an essential procedure for the welding, which removes the weld root from the back side before welding the back weld. The macroscopic cross-section of the weld joint after back chipping is shown in Fig. 12 .

Lane Community College 2014 Advanced Technology Division Fabrication/Welding Technology FABRICATION/WELDING REQUIRED TOOLS & SUPPLIES LIST FABRICATION WELDING 1 FABRICATION/WELDING 3

19/04/2010 · TECHNIP KT INDIA LIMITED. MRPL MANGALORE -CDU VDU HEATERS WELDING PROCEDURE SPECIFICATION ( QW – 482 AS PER ASME SECTION IX ) : TPKTI/MRPL/772/WPS-01 Welding Procedure Specification No :TPKTI/669/HGU/PQR/001 Supporting PQR No :SMAW Welding …

26/11/2010 · current back chip tool is a 41/2 grinder with tuff cut tct blade. its a bit of a beast but does the job. saw a picture once of long reach air grinder 90degree end with a 50mm tct blade for back chipping .

Misc Welding Products — Welspring Universal

SHIELDED METAL-ARC WELDING AND WEARFACING

The residual stress of conventional welding (CW) or a single arc welding (SAW) is calculated too. Moreover, the welding residual stress field of thick metal plates welded by DSDAW was carried out and compared with that of the CW method with back chipping. The result shows that the DSDAW technology had some excellent characteristics of smaller angular deformation, lower residual peak …

a range of welding helmets and filters with features that are just right for you. Follow the easy-to-use selection guide below to find the helmet and filter with features …

Weldingchipping hammer is brand new never used. Premium Estwing hammers are made in the USA. What you see is what you get. Items are packaged with care and shipped promptly after payment is …

solidified glassy product, slag should be removed by chipping or with a wire brush. Gas metal arc welding (GMAW): This process is also referred to as metal inert-gas (MIG) welding uses an …

Replace percussion or impact riveting with: a) welding , unless chipping is also required in the weld preparation; b) high strength bolts ; or c) compression riveting. 2. Replace chipping with grinding , Arc-air process or flame gouging .

A maintenance contractor was grinding a repair weld on a Dragline using a 125mm electric angle grinder when it is believed the tool jammed. On release the disc shattered and a fragment penetrated the eye protection of the welding helmet being worn. The employee suffered permanent loss of …

Eye injury can occur from the intense light and radiation that a welding arc can produce. Eye injury can also occur from hot slag and other metal debris that can fly off from the weld during cooling, chipping …

When welding like this, positive to the piece will create more heat and deeper penetration with less weld width, where negative to the piece will mean less penetration and wider weld width. As a guide negative to the hand piece for heavier materials and positive for light materials.

This new technology can realize no back chipping for thick plate welding. Furthermore, it has the potential advantages for the implementation of automatic welding for thick plate. Furthermore, it has the potential advantages for the implementation of automatic welding for thick plate.

Weld Design Menu. The following are welding related theory & application terms and definitions. ACETONE: A flammable, volatile liquid used in acetylene cylinders to dissolve and stabilize acetylene under high pressure.

Comments

4 Responses to “Back chipping in welding pdf”

28/03/2010 · Back grinding or chipping is done to remove slag on multiple pass welds. You do not want slag or any other impurities to be embeded in the weld. Reply: Anonymous Poster #5 In reply to #3. Re: Question on welding 03/27/2010 4:03 AM. Back grinding or chipping is done to remove slag on multiple pass welds. You do not want slag or any other impurities to be embeded in the weld. Is technically

Development of equipment and tools for back-chipping of welds

Eye injury can occur from the intense light and radiation that a welding arc can produce. Eye injury can also occur from hot slag and other metal debris that can fly off from the weld during cooling, chipping …

Bastex Chipping Slag Hammer Wire Welding Brush. 2 in 1

Australia’s leading online specialty welding shop. Selling a full range of welding machines, cutting machines, safety equipments, accessories and consumables at heavily discounted prices.

ESAB Compatible Owner’s Manual Cobra Welding Systems

FABRICATION/WELDING REQUIRED TOOLS & SUPPLIES LIST

Double-sided double arc welding (DSAW), a high efficiency method requiring no back chipping for welding thick plate of high-strength low-alloy steel was used in this study. Gas metal arc welding

Welding Cutting and Brazing Student Safety Guidelines

Welding Pennsylvania College of Technology